Why North Fork?

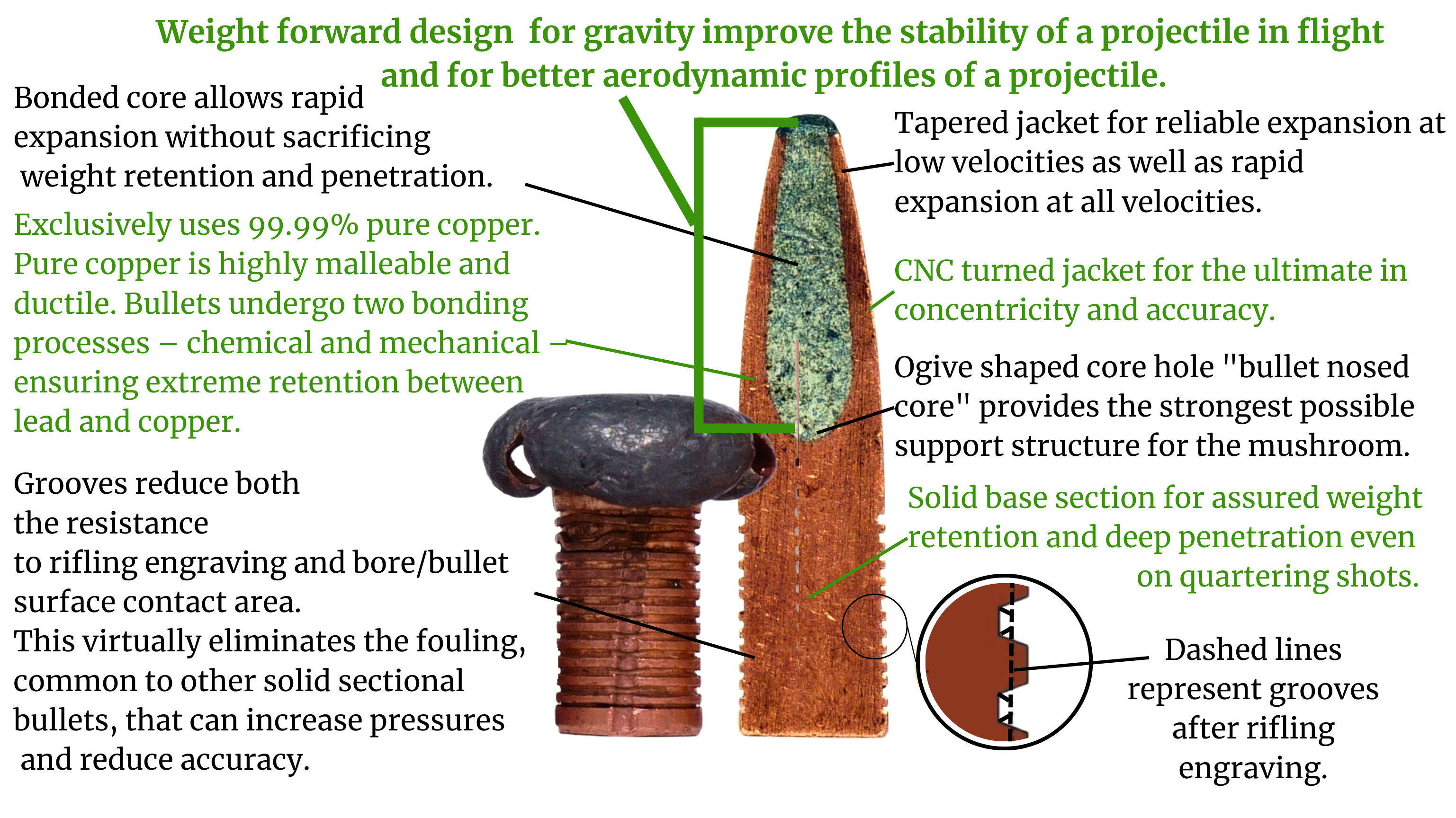

Choosing the right bullet can make the difference between a successful hunt and a failed one. What gives a bullet its true performance isn’t just the so-called “energy transfer” — it’s whether the bullet can reach the vital organs. That’s why a hunter needs a bullet that expands reliably and penetrates deeply. A high-quality bullet must hold together even when striking hard bone, and it shouldn’t deflect if the angle of impact is slightly off.

North Fork bullets remain intact under the massive pressure of impact, which allows them to penetrate straight and deep without breaking apart or deforming. Choose North Fork for a bullet that delivers maximum performance in every possible hunting condition.